Engineering Paint Curing Agent - Factory, Suppliers, Manufacturers from China

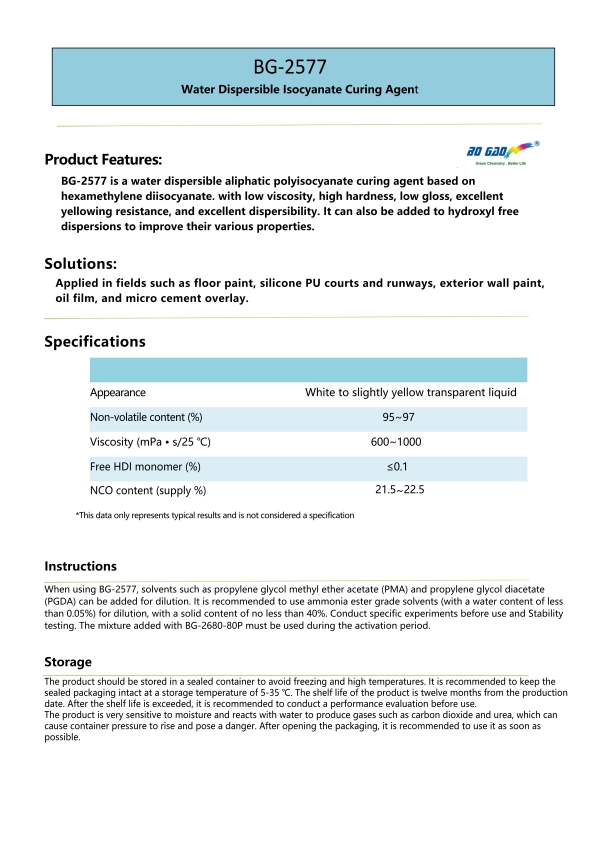

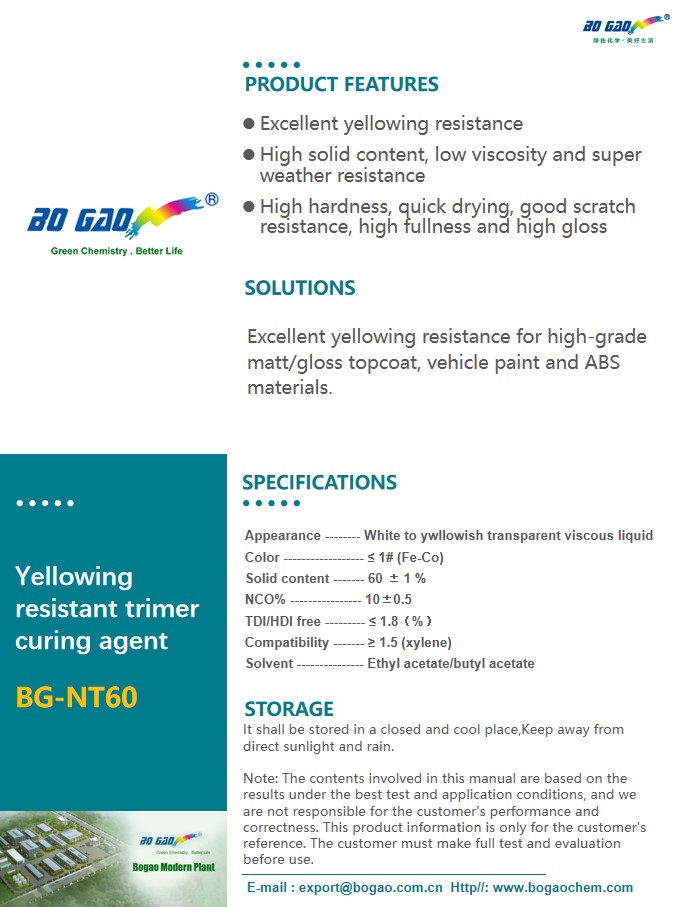

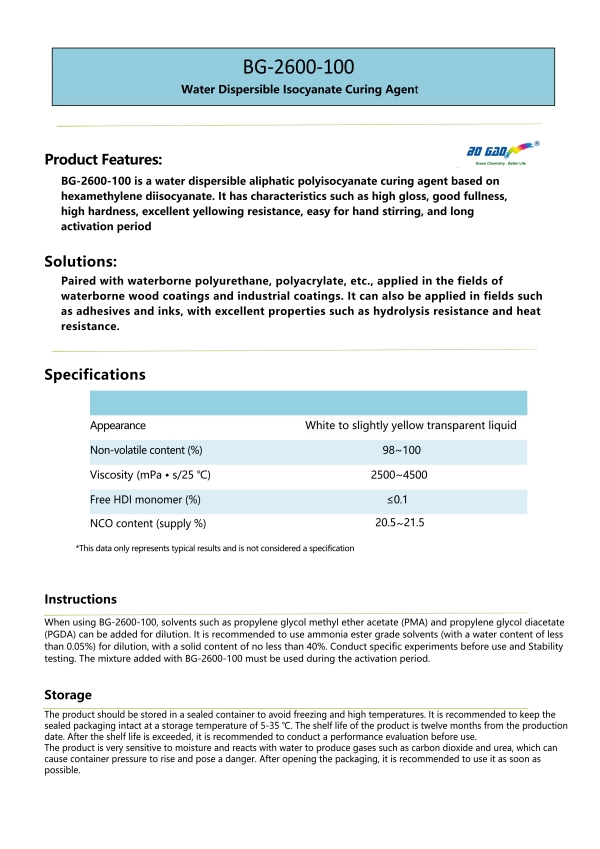

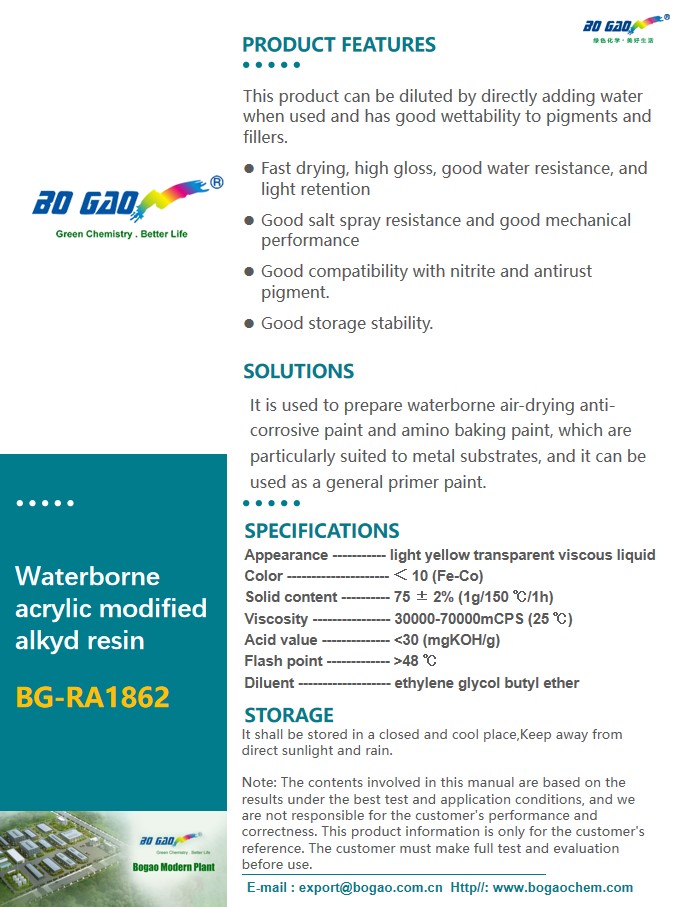

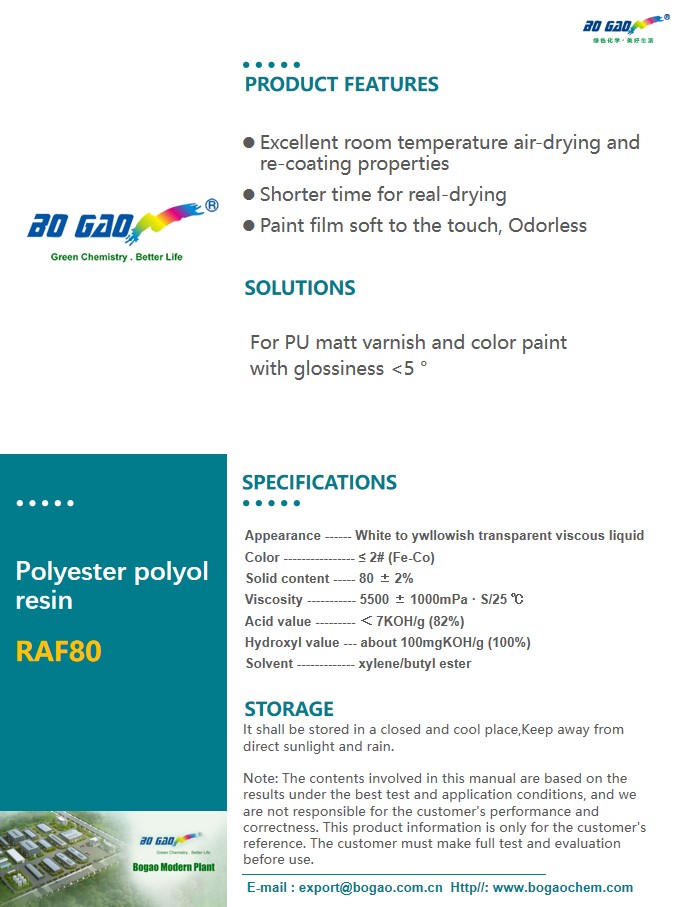

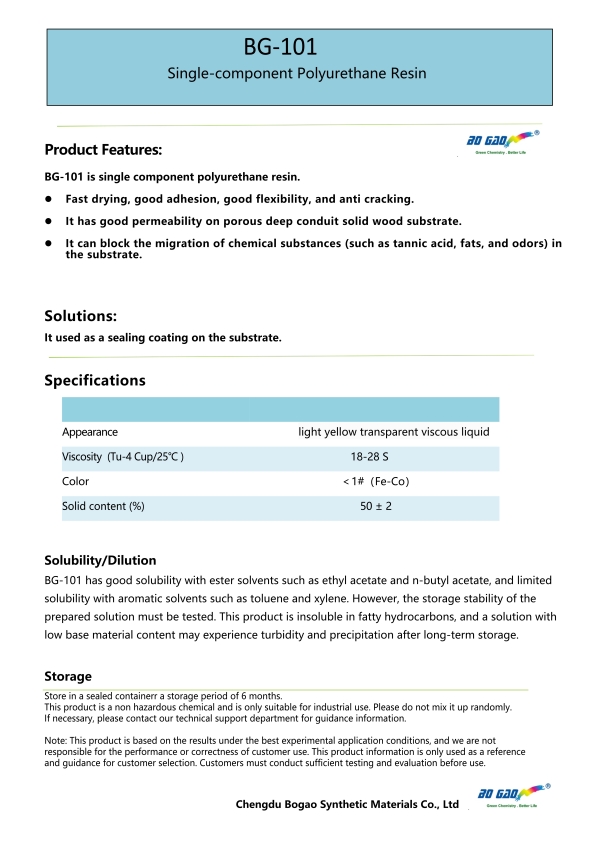

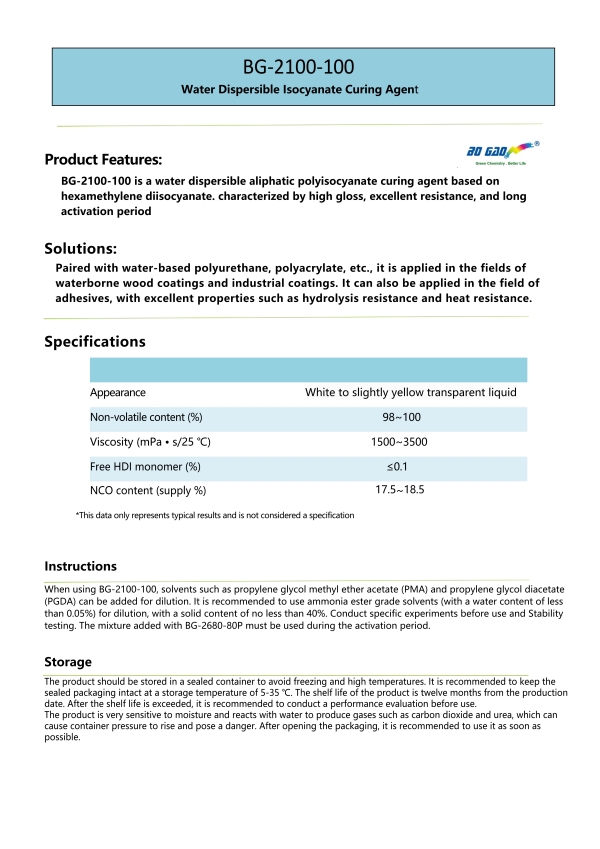

Using a total scientific good quality management process, superior high quality and excellent faith, we get great name and occupied this field for Engineering Paint Curing Agent, Anti-Corrosion Coating Hardener , Exterior Paints Hardener , Common Epoxy Hardener ,Anti-Corrosion Coating Hardener . Water-based curing agents, water-based resins, polyurethane curing agents, alkyd resins, acrylic resins, and auxiliary materials for coatings are the main areas of concentration for Bogao Enterprise. Its materials are widely utilized in polyurethane inks, industrial adhesives, new energy car components coatings, wood coatings, and water-based engineering machinery coatings. The product will supply to all over the world, such as Europe, America, Australia,Botswana, UK,Mexico, Istanbul.Waterborne coatings are usually composed of: water-based resin, pigments and fillers, additives, and water. Some waterborne coatings may contain some organic solvents due to the need of resin synthesis or formulation design. Among them, waterborne resin is the main film-forming substance of waterborne coatings, and its dosage in waterborne coatings usually accounts for 60%~85% of the total formulation. Its performance directly affects the final performance of waterborne coatings (such as storage stability, construction performance, physical and chemical properties of film-forming substances, etc.), so the selection of waterborne resin is crucial, and is the most critical determination in formulation design.

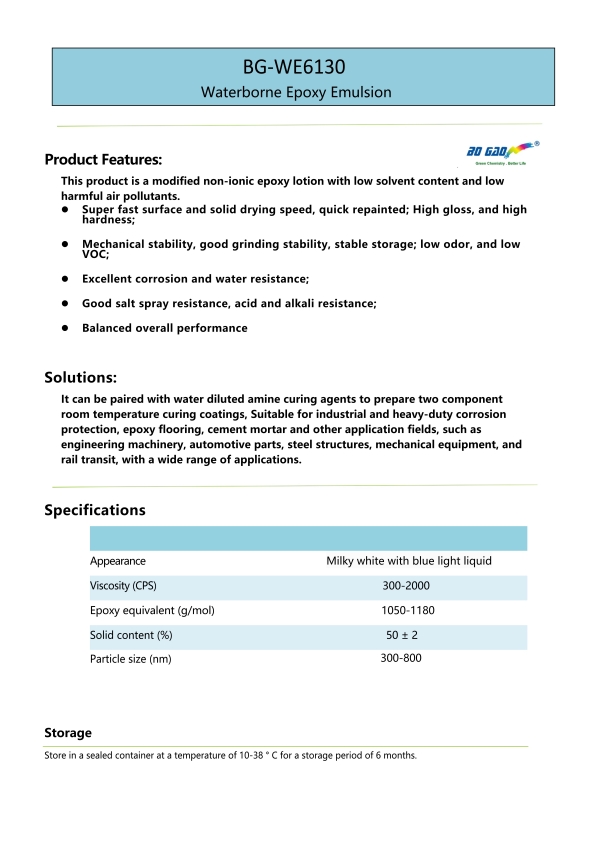

Related Products