Manufacturer for Wood Table Top Coating Resin - Polyester Polyol Resin – RAF80 – Bogao

Manufacturer for Wood Table Top Coating Resin - Polyester Polyol Resin – RAF80 – Bogao Detail:

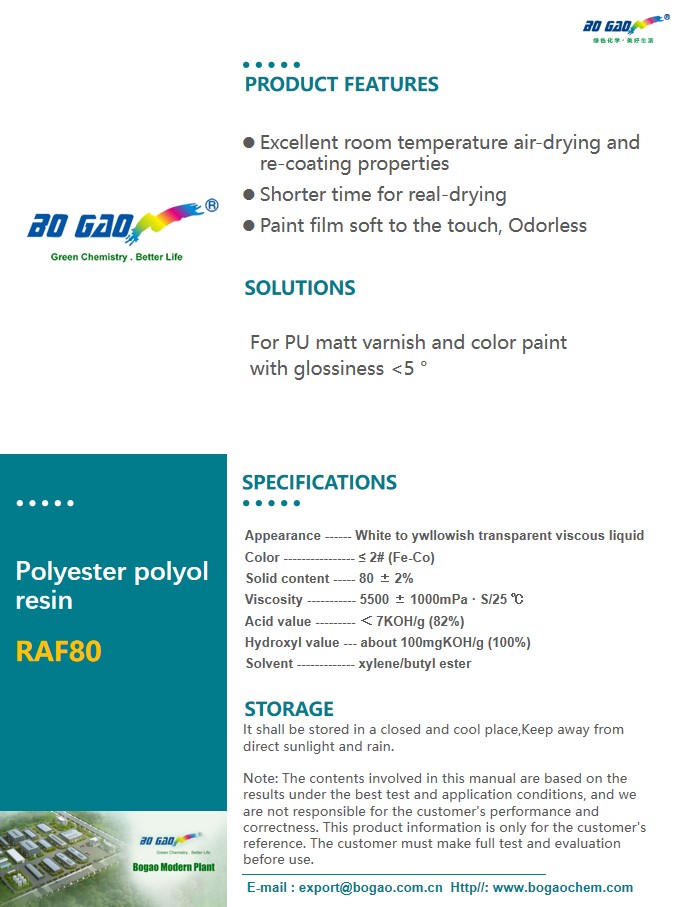

Solutions

For PU matt varnish and color paint with glossiness <5 °

Specifications

| Appearance | white to yellowish transparent viscous liquid |

| Color | < 2 # (Fe Co) |

| Solid content | 82 ± 1% (150 ℃ * 1H) |

| Viscosity | 5500 ± 1000mPa · S/25 ℃ (bro okfieid. 25 ℃) |

| Acid value | < 7KOH/g (82%) |

| Hydroxyl value | about 100mgKOH/g (100%) |

| Solvent | xylene/butyl ester |

Storage

Sealed storage in a cool place,Keep away from direct sunlight and rain.

Note: The contents involved in this manual are based on the results under the best test and application conditions, and we are not responsible for the customer’s performance and correctness. This product information is only for the customer’s reference. The customer must make full test and evaluation before use.

Disclaimer

The company believes the manual contains information data and the reliability of the recommendations,but about product features,quality,safety and other properties,the content involved in this manual are for reference only.To avoid doubt,ensure that the company does not make any express or implied,including merchantability and applicability,and unless the company in writing to specify other content. Any information provided by the instruction should not be regarded as the exploitation of the patent technology licensing.should not be regarded as the premise of without permission from the patent all induced by exploitation of the patent technology.We recommend that users should according to the details of this product safety data sheet for safety and reasonable operation,please contact us before using this product to determine the characteristics of the product.

We actively introduced advanced equipment from both home and abroad. At the same time, our company has an expert team dedicated to developing a series of curing agents and resins. If you are interested, please feel free to contact us. We look forward to establishing a long-term and stable cooperative relationship with you.

We sincerely welcome you to visit us at any time, and we will provide customers with more convenient and considerate service and support.

Product detail pictures:

Related Product Guide:

We emphasize progress and introduce new merchandise into the market each and every year for Manufacturer for Wood Table Top Coating Resin - Polyester Polyol Resin – RAF80 – Bogao , The product will supply to all over the world, such as: Swiss, New York, Romania, Adhesives are typically liquid or paste in nature. Because these adhesives must be dried before they can be used in bonding, the curing process of adhesives is also critical. If the curing is poor or you don't know what to look for when curing, it will have a significant impact on the bonding of articles, even if the adhesive you use is enough. The curing reaction of adhesive is a chemical reaction that is used to obtain and improve bonding strength and other properties (polymerization, crosslinking). Curing is an important step in achieving good bonding characteristics. The adhesive's strength will be at its peak only once it has completely hardened.Curing is classified into three stages: initial curing, basic curing, and post curing.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!